Mastering PDR equipment safely repairs minor car damage without painting or replacing parts. Interactive training with tools like dent pullers, tabbed tools, and suction cups enhances staff skills. Practical scenarios mimicking real collision damage prepare employees for diverse PDR challenges.

Training staff on using PDR (Paintless Dent Repair) equipment effectively is crucial for any automotive service center. This comprehensive guide walks you through three key steps: understanding PDR equipment basics and safety precautions, demonstrating correct usage through interactive training sessions, and implementing practice scenarios for hands-on experience and constructive feedback. By following these strategies, you empower your team to master PDR equipment, ensuring superior quality and customer satisfaction.

- Understand PDR Equipment Basics and Safety Precautions

- Demonstrate Correct Usage Through Interactive Training Sessions

- Implement Practice Scenarios for Hands-On Experience and Feedback

Understand PDR Equipment Basics and Safety Precautions

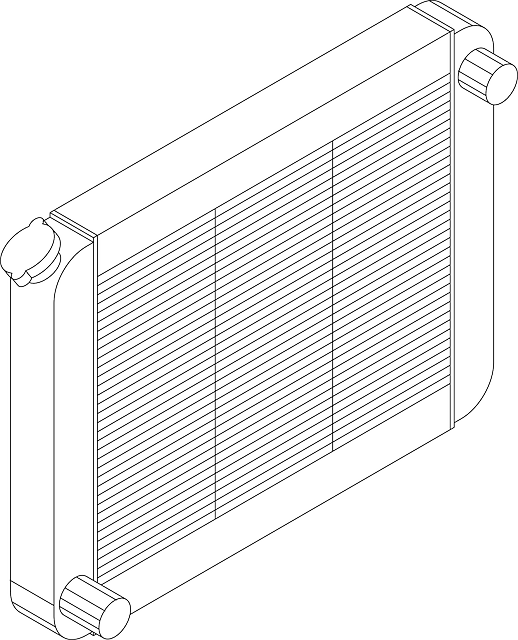

Before diving into using PDR equipment, it’s crucial to grasp its basic functionalities and safety precautions. PDR, or Paintless Dent Repair, is a specialized technique for repairing minor car damage, such as dents and scratches, without painting or replacing parts. Understanding the various tools, including dent pullers, tabbed tools, and suction cups, is essential for effective use. Each tool serves a specific purpose in removing dents from a vehicle’s body panel, making it vital to know their capabilities and limitations.

Safety should be at the forefront of every PDR session. Operators must don appropriate personal protective equipment (PPE), like gloves and safety goggles, to prevent injuries from tools or debris. Additionally, familiarizing oneself with the equipment’s controls and mechanisms ensures a safe working environment in an automotive body shop or during vehicle repair services. Knowing how to manage pressure, heat, and other parameters is key to successful PDR, enabling technicians to deliver high-quality car damage repairs without causing further harm.

Demonstrate Correct Usage Through Interactive Training Sessions

During training sessions, it’s essential to demonstrate the correct usage of PDR equipment through interactive exercises. This hands-on approach allows staff to experience the tools firsthand, fostering a deeper understanding of their capabilities and limitations. Begin with a thorough overview of each tool, highlighting its purpose and unique features, followed by practical demonstrations. Encourage employees to ask questions and provide clear, concise instructions for each step of the repair process, focusing on common challenges encountered in fleet repair services and vehicle restoration.

Interactive training sessions should also incorporate scenarios that mimic real-world situations. For instance, set up damaged vehicles with various scratch repairs needed and let staff practice using PDR equipment to address them. This not only enhances their technical skills but also hones their problem-solving abilities, ensuring they’re ready to tackle any challenge that comes their way in the field.

Implement Practice Scenarios for Hands-On Experience and Feedback

To ensure staff are prepared for real-world scenarios when using PDR equipment, implement practice scenarios that mimic actual collision damage repair and vehicle restoration tasks. These hands-on exercises allow employees to gain practical experience with the tools and techniques involved in car paint services. By creating simulated environments, trainers can provide immediate feedback on their performance, enabling them to refine their skills quickly.

The scenarios should cover a range of potential issues, from minor dents and scratches to more complex repairs, such as panel replacement or large areas of damaged paint. This comprehensive approach ensures that staff are versatile and capable of handling various challenges related to PDR equipment use in collision damage repair and vehicle restoration processes.

Training staff on using PDR (Paintless Dent Repair) equipment effectively involves a structured approach. By understanding the basics and safety precautions, conducting interactive training sessions, and implementing hands-on practice scenarios, you empower your team to use PDR equipment proficiently, ensuring high-quality work and enhancing customer satisfaction. These steps are pivotal in navigating the world of PDR, fostering a competent and efficient workforce.