PDR equipment revolutionizes dent removal on aluminum panels, offering precise, efficient, and non-invasive solutions compared to traditional methods. Specialized tools gently push out dents without damaging paintwork, minimizing repainting needs and providing quick, cost-effective collision repair services for minor accidents and door dings.

Aluminum panel damage can be a challenge for auto body repair, but Professional Dent Repair (PDR) equipment offers efficient solutions. This non-invasive technique leverages specialized tools to remove dents and scratches from aluminum surfaces with remarkable precision. By understanding the unique characteristics of PDR equipment designed for aluminum, technicians can optimize dent removal processes, ensuring high-quality repairs while minimizing damage to these lightweight yet durable materials.

- Understanding PDR Equipment for Aluminum Panels

- How PDR Tools Facilitate Efficient Dent Removal

- Benefits and Applications of PDR on Aluminum Surfaces

Understanding PDR Equipment for Aluminum Panels

PDR equipment is specifically designed for dent removal on aluminum panels, a process known as Paintless Dent Repair (PDR). This innovative technique has revolutionized both auto painting and collision repair industries by offering a cost-effective, time-saving alternative to traditional panel replacement. PDR tools work by accessing the backside of the damaged area, allowing technicians to gently push out the dent without damaging the surrounding paintwork.

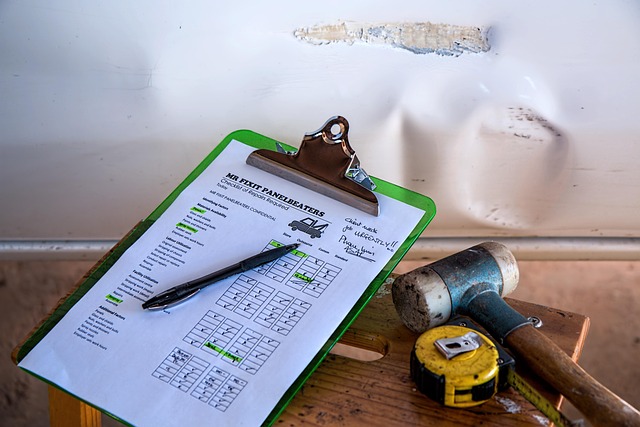

Aluminum panels, common in modern vehicles, pose unique challenges due to their soft metal nature and delicate paint finish. Specialized PDR equipment is required to accommodate these factors. Tools like dauntless guns, tabbing tools, and pullers are utilized to precisely manipulate the metal without causing further harm. Understanding how this equipment functions and its capabilities is essential for body shop services aiming to provide top-notch collision repair while minimizing repainting requirements.

How PDR Tools Facilitate Efficient Dent Removal

PDR (Paintless Dent Repair) equipment has revolutionized the way dent removal is performed on aluminum panels. These specialized tools allow for precise and efficient dent correction, minimizing damage to the panel’s finish. By using specialized PDR tools, collision repair shops can offer quick and cost-effective auto body services, appealing to customers seeking top-notch results without extensive frame straightening.

The advanced technology incorporated into modern PDR equipment enables technicians to access and manipulate hard-to-reach areas with ease. This versatility is particularly beneficial for aluminum panels, known for their thin gauge and delicate nature. With the right PDR tools, professionals can achieve seamless dent removal, ensuring the panel’s original integrity and beauty are preserved.

Benefits and Applications of PDR on Aluminum Surfaces

PDR (Paintless Dent Repair) equipment has revolutionized car body repair by offering a non-invasive method for removing dents and dings from various surfaces, including aluminum panels. The benefits of PDR on aluminum surfaces are numerous. Firstly, it preserves the original factory finish, ensuring that the repaired area retains its lustre and overall aesthetics. This is particularly advantageous for vehicles with intricate aluminum designs or those seeking to maintain a consistent, high-end appearance.

Additionally, PDR is highly efficient and cost-effective compared to traditional collision center methods. It eliminates the need for sanding, painting, and prolonged downtime, making it a faster and greener solution for car dent removal. Whether it’s minor accidents or door dings, PDR equipment allows technicians to restore cars to their pre-damage condition, showcasing the versatility of this modern repair technique in the automotive industry.

PDR (Paintless Dent Repair) equipment has proven to be a game-changer in dent removal, especially for aluminum panels. By utilizing specialized tools designed to facilitate precise and efficient work, professionals can restore damaged surfaces to their original condition, preserving the vehicle’s aesthetic value and minimizing repair costs. The benefits of PDR on aluminum are numerous, from enhanced structural integrity to the preservation of factory finishes, making it a preferred method in today’s automotive industry.